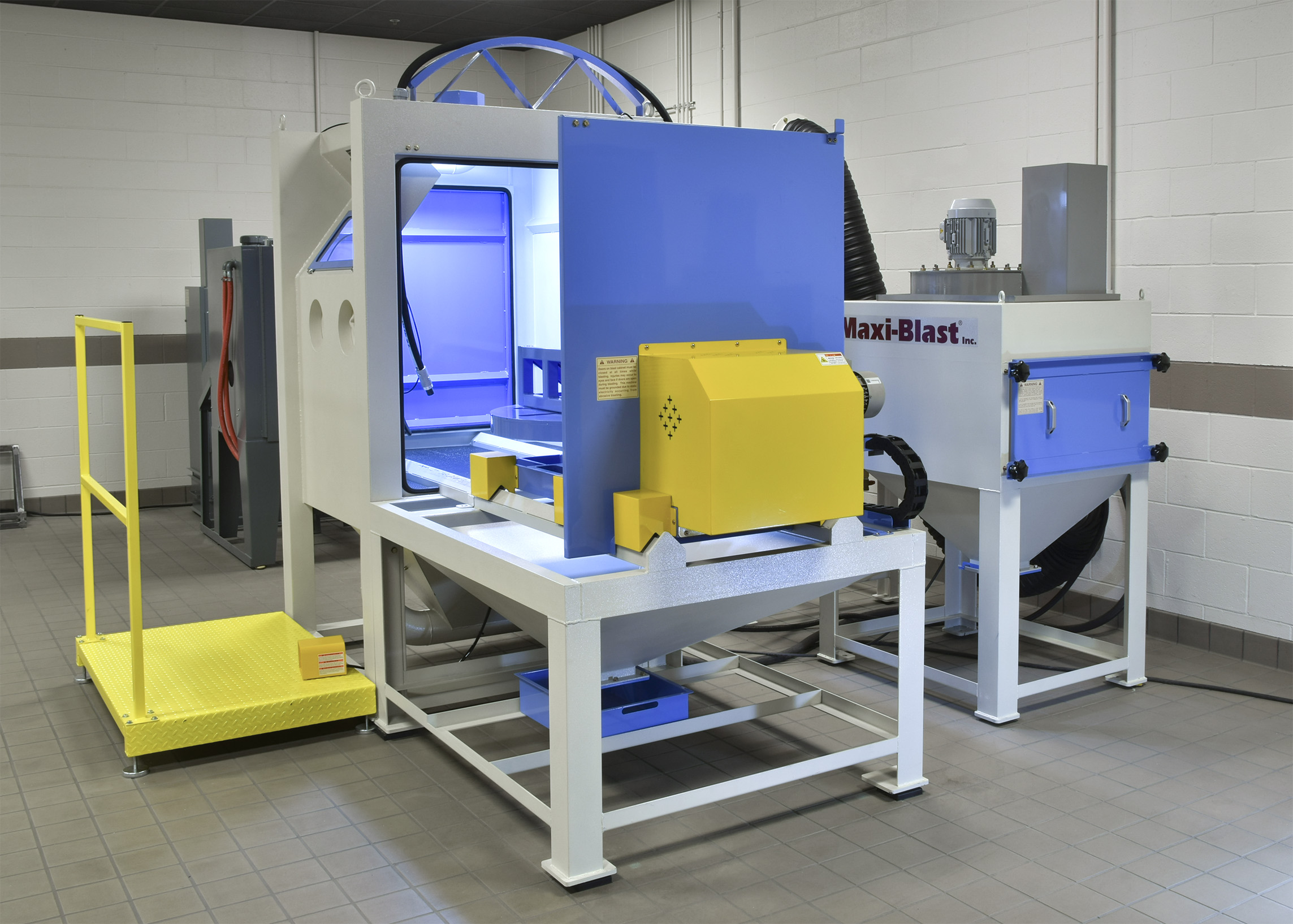

Specifically designed for blasting, reclaiming, and cleaning

of recyclable plastic media, our direct pressure dry blast

cabinet systems are completely self-contained for a dust-free,

non-toxic environment.

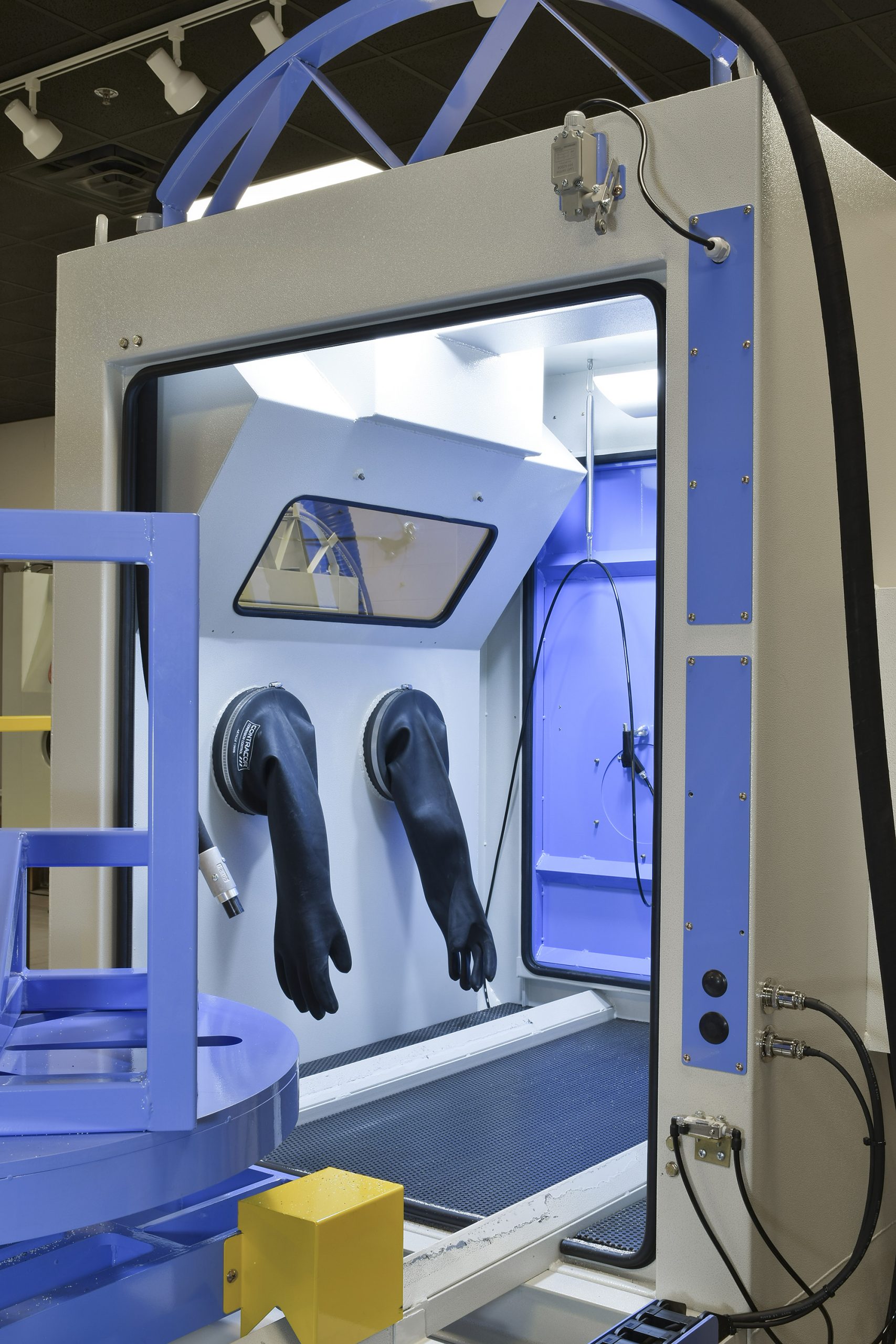

To ensure maximum operator visibility, dust is vacuumed

from the cabinet by means of a high efficiency blower located

on the clean air side of the dust collector. For easy maintenance,

the dust collector is equipped with an automatic/manual

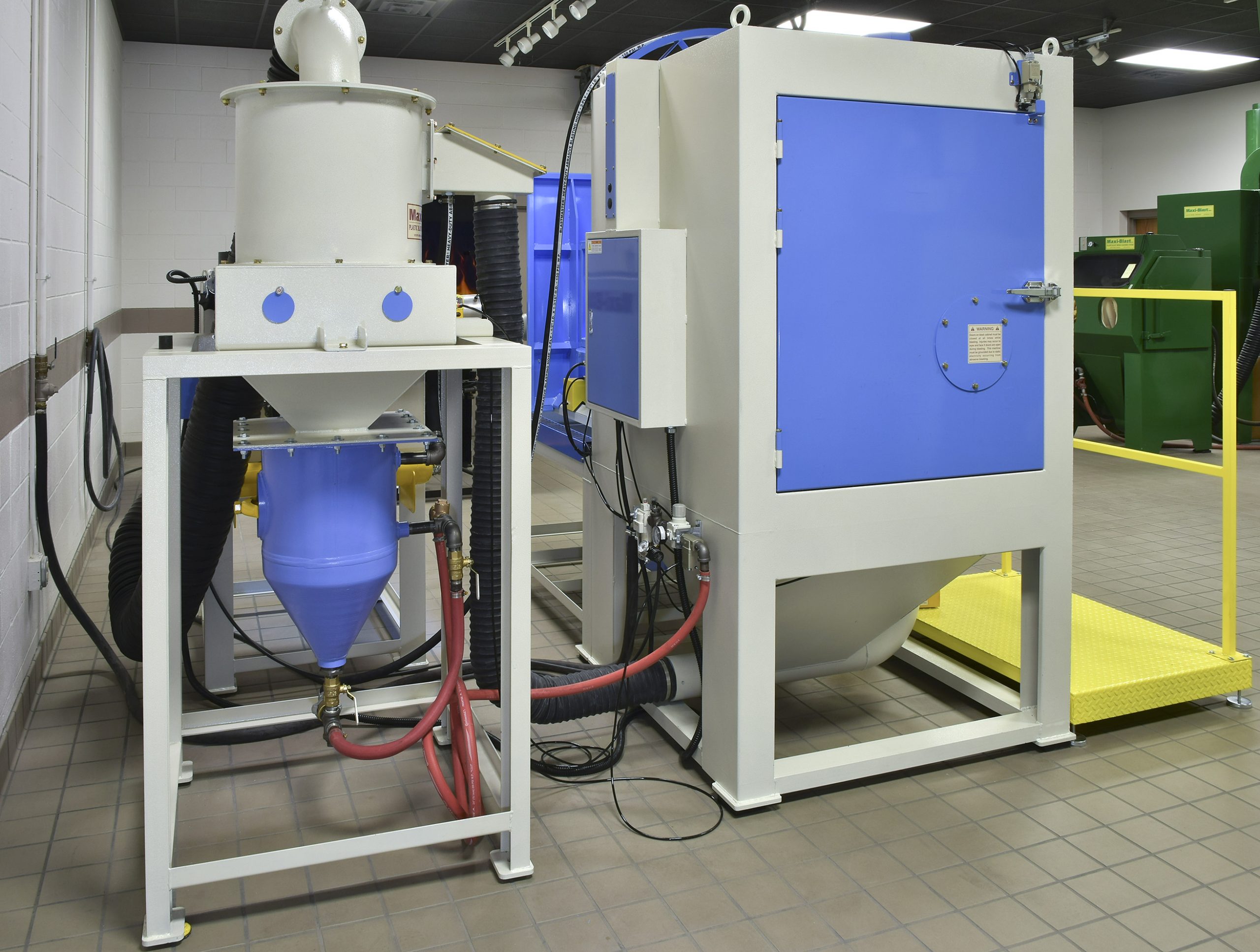

cartridge blow down valve. The clean, reusable media passes

through a vibrating screen to trap large contaminants and,

simultaneously, through a magnetic separator that filters out

ferrous contaminants before being stored for reuse. Reloading

of the media into the pressure vessel from the storage hopper

occurs automatically each time the operator releases the foot

pedal depressurizing the vessel.

To provide for smooth flow of the low-density plastic, a 60°

cone pressure vessel and hopper are standard. An adjustable

valve controls the feeding of media into the air stream.

These durable machines are built for years of reliable service

with plastic media or other abrasives. The cabinet and dust

collector are constructed of 11 gauge prime steel, all welded

construction. A variety of cabinet sizes are available.

Features

- Pneumatic safety door interlocks

- Safety view window, gloves, LED lights

- Foot-controlled blasting, durable blast hose

- Tungsten carbide blast nozzle

- Moisture separator and pressure regulator with gauge

- Vibrating screen for large contaminants

- Air blow-off gun

- Dust collector muffler

- 1.6 cu. ft. ASME coded pressure vessel

- Starter on systems with 3 phase electricals

- Media spill tray under track extension

- Push-button work car and door with mold rack

- Automatic exhaust valve

- Roof entry of blast hose

Pressure Blast Mold Cleaning System Specifications |

|||

|---|---|---|---|

| Model | Inside Cabinet Dimensions W x D x H |

Floor Space Cabinet & Dust Collector W x D x H |

Door Opening |

| MBK 4848 PDH-DC 200 |

48" x 48" x 48" | 114" x 108" x 96" | Swing Door 36" x 42" Trackside 36" x 45" |

| MBK 6060 PDH-DC 200 |

60" x 60" x 60" | 156" x 128" x 112" | Swing Door 48" x 46" Trackside 48" x 48" |

Available Features

- Extrusion screw port hole

- Magnetic separators

- Operator platform